What is an Acrylic Adhesive?

From construction to automotive and aerospace engineering, acrylic adhesives help form strong bonds between a wide range of substrates. In this article we’ll cover what they are, why they’re a great bonding solution, and how to find the right one.

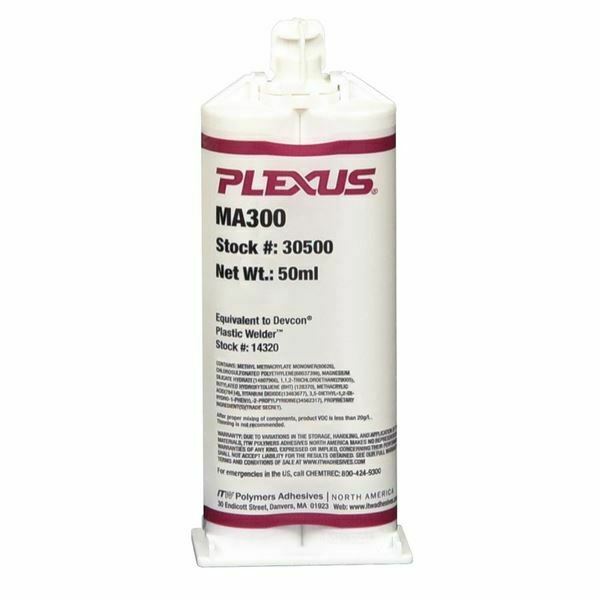

An acrylic adhesive (also known as methylmethacrylate, acrylate, or MMA) is a resin-based, two-part adhesive comprised of acrylic or methylacrylic polymers. They are extremely strong and efficient in bonding multiple objects together and are very environmentally resistant.

Why Acrylic Adhesives?

Acrylics are one of the three main types of structural adhesives— acrylic, epoxies and polyurethanes. What sets acrylic adhesives apart from the rest are the rapid strength development, and the ability to bond various metals and plastics often without a primer.

If you are looking for a structural adhesive, the selection process to determine whether you should use an acrylic, epoxy or urethane is about understanding the application and process requirements (what materials are being bonded, cure time, handling strength, environment conditions, etc.) and then choosing the technology that checks the most boxes in terms of your needs and wants.

If you are looking for an adhesive to bond metals, plastics or composites, want minimal extra steps for surface preparation, and need fast cycle times then an acrylic adhesive is probably a good choice for you.

Acrylic adhesives are also among the strongest adhesives available. This is largely due to two factors: their cohesion and adhesion properties.

- Cohesion is the measure of an adhesive’s ability to stick to itself.

- Adhesion is its ability to stick to other objects.

Acrylics have some of the best cohesion and adhesion in the industry. They also come in a wide range of cure time, cure temperature, viscosities and with a wide variety of special properties.

How to Find the Right Acrylic Adhesive

Finding the right product in this category really comes down to the application.

Acrylics are used for a wide range of applications ranging from signage fabrication to general manufacturing, to trucking and aerospace engineering, to construction and countertop fabrication.

There are three main features to consider when looking for the right acrylic for the job – viscosity, cure time and special properties.

#1. Viscosity

The first consideration is viscosity – how thick or runny your adhesive is. Acrylic adhesives come in a range of viscosities starting at liquid all the way up to a thick paste. The viscosity you need will come down to your working conditions.

Does your assembly have tight tolerances, or do you need an adhesive to cover a wide area of bonding surface? If so, you’ll want to go with an acrylic on the liquid side of the spectrum.

If you’re working on vertical or over-head surfaces, then you’ll want to go with a paste. These options won’t sag or slide down your surface, preventing weak bonds and an awful mess.

#2. Cure Time

The next consideration is cure time – how long it takes the adhesive to form a structural bond between your surfaces.

Sometimes you need a fast cure to get from one step in your process to the next. So, you’ll want to look for the fastest possible cure time.

Other times, you might want something that takes a little longer. Something that fits in your timing sequences. They key is to find the speed that works best for your processes. Check the technical data sheet (TDS) of your product and look for the specs for working time and handling time. This will tell you what you need to see if the adhesive in question will fit your desired process.

The working time is how much time you have to apply the adhesive, mate your parts, and get everything clamped or fixtured. If you have large parts or complex fixturing process, you may need a longer working time.

Fixture time or handling time is the amount of time it takes for the bonded assembly to reach a defined level of strength (often 100 PSI) which is sufficient to move the part to the next phase in the production process without damaging the bond. This is useful if your production involves post processing such as painting, sanding or additional assembly steps.

Many acrylic adhesives have “snap cure” technology which means they can reach 80% of their bonding strength within the first few hours of curing. This is one of the reasons that acrylics have rapidly replaced epoxies and other assembly techniques as they are very suited to high output manufacturing, eliminating downtime and bottlenecks compared to traditional methods.

#3. Special Properties

The last consideration are application-specific special properties.

When you start shopping for an acrylic adhesive, you’ll quickly realize there are many options. These special properties are usually industry-specific, which will help narrow down your search.

Some examples of special properties include added color, UV resistance, high temperature resistance, increased flexibility and glass spacer beads. There are also acrylic adhesives that specialize on specific surfaces like low surface energy materials or dissimilar substrate bonding.

You may also be looking for an adhesive product that meets certain certifications or specifications such as UL listing, Greenguard, Mil Spec, or NSN number.

The point here is to have your application and requirements in mind. You’ll probably find a specialized acrylic that can improve your process.

The Benefits of Structural Acrylic Adhesives

Beyond strength, acrylic adhesives provide a wide range of generalized benefits for construction, assembly and manufacturing projects. Here are the biggest.

#1. Lightweight & Optimize

Acrylic adhesives (and all structural adhesives) bond across a continuous, even area. That distributes stress across the surface of the material instead of concentrating stress at certain points. This even distribution creates fewer failure points of the structure and improves the overall durability.

It also allows you to use thinner materials at bonding points. That means you can light weight and downgauge your materials and still maintain the same necessary strength. You can ship, move and create your product with less energy and resources because acrylic adhesive bonds allow up to 37% lower mass of assembly.

#2. Save Time & Money by Replacing Traditional Methods

Acrylic adhesives save manufacturers time and money.

Bonding with acrylics reduces the number of manufacturing steps required. That can help you speed up assembly times by up to 60%. Acrylic adhesives require less surface preparation. They also come in fast-dispensing cartridges with a variety of quick cure rate times. To top it off, they don’t require post processing once bonded.

Depending on your assembly and the methods you’re using right now, acrylic adhesives can reduce total cost of assembly by up to 50%.

A big reason for that is they don’t require specialized labor. For you, that means lower pay requirements, and it can address some problems your business might be facing due to labor shortages. On top of the labor savings, when compared to other assembly methods, using acrylic adhesives can reduce associated equipment costs.

Also, strength to surface area per dollar spent ratio is higher (i.e., more cost-effective) due to simplified manufacturing and reduced inventory.

#3. Bond Dissimilar Materials

Today’s manufacturers and construction firms use a wide variety of materials. Without the right products, bonding dissimilar materials can be a challenge due to the varying chemical properties of different substrates.

For example, polymer materials are popular in automotive applications because of their low weight, high strength and low cost. But how do you bond a polymer to metal components?

Structural adhesives are the answer. They can bond dissimilar substrates quickly and effectively with minimal surface preparation. This allows for more design freedom without adding to production time or sacrificing durability.

Conclusion – Know What You’re Buying

Finding the right acrylic adhesive can be overwhelming. As long as you know what you’re looking to do, you’ll definitely find an acrylic adhesive that will help make your processes and you end-products better.

At Chemical Concepts, we’ve been on the forefront of acrylic structural adhesive and we put the customers’ requirements first. So save yourself some time and energy! Our experts can help you find the product best suited for your application.

Get in touch today to find a solution that meets your needs quickly and easily without all the headaches.

Let’s get into what to look for in an acrylic adhesive.

Liquid vs. Paste

Acrylic adhesives are available in either liquid or paste form. How do you know which one is right for your specific project? Liquid acrylic adhesives are commonly applied with a brush or damp cloth and are used for upholstery or carpentry applications. Liquid acrylic adhesives are more flexible and thinner, so projects that require a seamless appearance are best performed with a liquid adhesive.

Paste acrylic adhesives are more commonly found, and can be used on virtually any surface for any application. Paste acrylic adhesives can also be used in conjunction with liquid acrylic adhesives for an even stronger bond. The paste texture is used often to “sandwich” two objects together for a completely permanent bond.

Temporary Acrylic Adhesives

While most acrylic adhesives are praised for their permanence, a temporary acrylic adhesive is also available. These adhesives are constructed with low viscosity, cohesion, and adhesion, so they can be easily broken apart with water or adhesive removers, unlike traditional permanent acrylic adhesives.

Acrylic adhesives are a huge market for us at Chemical Concepts, and we want to show you just what they can do! For more information about the acrylic adhesives that we stock, give us a call, toll-free, at 1-800-220-1966 or send us an email at [email protected]. We look forward to hearing from you!