How Manufacturers are Cutting Weight with Titanium Fasteners

Reducing weight without compromising strength–otherwise known as “light-weighting”– has become a driving force for manufacturers in several industries, most notably the automotive and aerospace industries. With this new impetus to cut weight wherever possible, many manufacturers are turning to titanium fasteners as a viable alternative to stainless steel when assembling their final products. The blog explores why and how to decide whether titanium fasteners suit your applications.

While titanium fasteners offer many advantages, they are only practical for certain applications. To understand where they are best used, we need to understand what drives manufacturers to opt for titanium and some of its key benefits.

What is Driving Manufacturers to Choose Titanium?

In the aerospace and automotive industries, reducing weight while maintaining strength is essential for manufacturers to meet increasing emissions regulations and improve range. Lighter-weight aircraft and vehicles can go farther and travel faster, and with the increasing shift to electric vehicles, extending the range of a full battery charge is a key way manufacturers can stand out from the competition.

In the medical and life science industries, titanium is a sought-after material for its combination of lightweight, durability and biocompatibility. Titanium offers greater longevity in many applications and indicates a larger shift across all industries toward innovation and using advanced materials.

The Benefits of Titanium Fasteners

Titanium has clear advantages over stainless steel and other common metals used for parts and fasteners in many assemblies. Here are some of the most widely applicable benefits.

1. Light-weighting

Titanium is 45% lighter than stainless steel, making it ideal for quickly reducing weight in an assembly. That lower weight improves performance in the aerospace, automotive and sports industries, leading to faster top-end speed and better fuel efficiency.

2. High Strength-to-Weight Ratio

Titanium has one of the highest strength-to-weight ratios of any metal. It can provide equivalent or better strength than stainless steel and other traditional materials. This benefit also allows manufacturers to use less material in some places, further reducing weight while maintaining the required strength and durability of the final product.

3. Corrosion and Rust Resistance

In tandem with its strength, titanium offers superior corrosion and rust resistance. It’s more resistant to common problems like crevice corrosion, pitting, and stress corrosion cracking than stainless steel, further maintaining the durability and longevity of end products. This is essential for manufacturers in the marine and chemical industries.

4. Temperature Tolerance

Titanium is also more resistant to temperature. It maintains its original properties in extreme temperatures—both hot and cold. It also performs well in high-temperature environments, maintaining structural integrity in extremely hot temperatures.

5. Non-Magnetic and Non-Toxic Properties

Biocompatibility is a crucial criterion for a material’s use in the life science and biomedical fields. Titanium is non-toxic and non-magnetic, making it useful in many medical applications, from implants to fasteners to MRI machines.

6. Longevity and Durability

Titanium fasteners last longer in harsh environments due to their corrosion resistance and durability, reducing maintenance needs. In high-stress applications, they exhibit excellent fatigue resistance compared to stainless steel.

7. Lower Thermal Expansion

Titanium has a lower coefficient of thermal expansion than stainless steel, meaning it undergoes less dimensional change with temperature shifts. This stability makes it ideal for precision engineering.

The Potential Drawbacks of Titanium Fasteners

While these benefits are all enticing, it’s important to note that titanium fasteners do have some potential drawbacks to consider. The main one is price. Titanium is more expensive than traditional stainless steel in terms of raw material and machining costs.

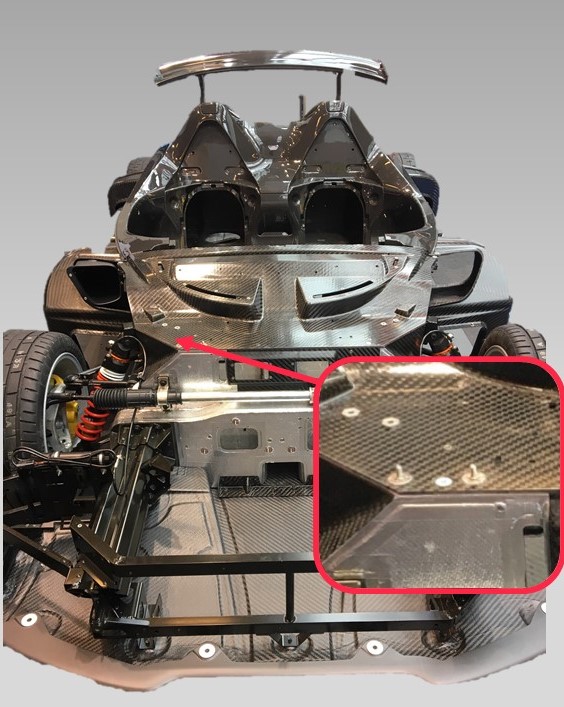

If cost is not a deterrent in your manufacturing process, and you strive to get the highest performance possible, titanium fasteners are a great way to cut weight in your final build. This is why titanium is used in specialty fasteners for hyper-cars —the performance gains justify the use of exotic materials, and the higher price point of these vehicles can accommodate the added cost.

In addition, while strong and highly resistant to corrosion, titanium can be brittle and susceptible to galvanic corrosion if used improperly with other metals. Therefore, it’s important to consider these factors in design so the right materials are selected.

The Challenge of Sourcing Titanium Fasteners

Not many companies produce titanium fasteners, especially fasteners that meet strict industry standards for aerospace and automotive manufacturing. Challenges like high raw material costs and long lead times can prevent fastener manufacturers from expanding their portfolio to include titanium product lines. On top of that, titanium fasteners tend to be used in complex manufacturing scenarios, and some customization and planning are required from both parties to meet the needs of the final design. Because of these challenges, many manufacturers forego finding a fastener supplier and decide to produce the titanium fasteners they need in-house.

If your company plans to or is already spending money on R&D to find ways to lightweight its products, finding a titanium fastener supplier can be a net cost savings despite the higher titanium costs over stainless steel. The right supplier can work with your design drawings to find viable ways to join the different parts of your end product using their portfolio of available fasteners.

Types of Titanium Fasteners

There are many possibilities for machining custom titanium fasteners to meet the exact needs of a design. Manufacturers looking for lightweight, high-performance parts might want to consider these technologies for titanium specialty fasteners as a starting point:

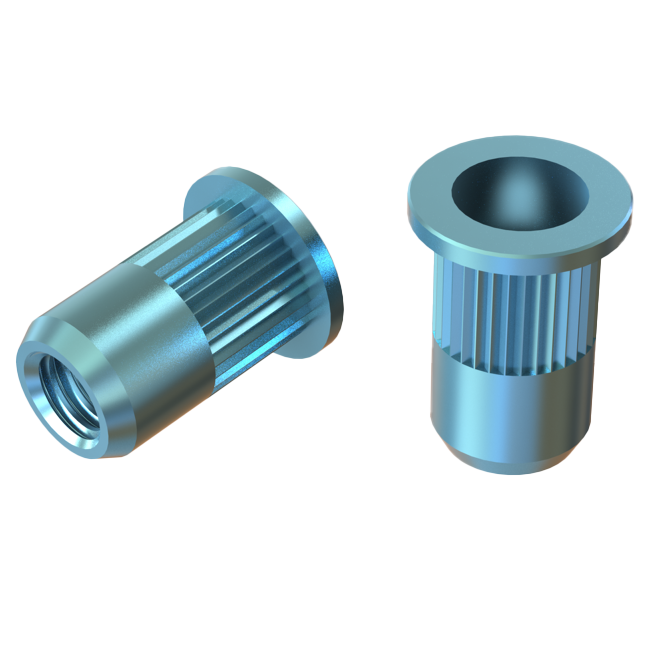

- Titanium Rivet Nuts: Rivet nuts are threaded fasteners that provide secure connections in thin materials, especially where access is limited to one side. When made of titanium, they gain all the benefits of the material, like high strength-to-weight ratio, corrosion resistance and ability to perform under extreme temperatures.

- Titanium Bonding Fasteners: Bonding fasteners are metal components that are adhered or embedded to surfaces. These parts can be adhered to the surface with a structural adhesive or high bond tape, or cast into the material with rotational molding or other casting processes. Surface mounted fasteners provide ideal attachment points without the need for drilling or welding. Titanium surface mounted fasteners allow manufacturers to create lighter-weight, higher-strength bond points in their assemblies.

- Titanium Threaded Inserts: Threaded inserts are used to create durable internal threads in soft or thin materials to allow bolts and screws to fasten securely. When made of titanium, threaded inserts offer greater resistance to environmental factors and corrosion.

There are also different grades of titanium which you might want to be aware of. Grade 2 Titanium is most commonly used for fasteners. Here is a good resource for learning more about grades of titanium.

Conclusion: If You Need to Lightweight, You Need Titanium

If your company is looking to reduce weight in premium constructions, replacing stainless steel fasteners with titanium is a great way to do just that. Titanium is a lightweight, high-strength, resistant material that can ensure your build quality improves while reducing weight.

Finding the right titanium fastener supplier is the key to unlocking those benefits. At Chemical Concepts, we partner with leading fastener manufacturers to provide your business with cutting-edge products. We are the exclusive North American master distributor for Specialinsert – a world leader in highly specialized custom-made titanium fasteners. If you need a high-performance, lightweight fastener for your application, we can help.

We’re also experts on all sorts of products designed to bond materials, including chemical adhesives, tapes, and mechanical fasteners. We can help your company find the right solution to bond the materials in your assembly.

If you have any specific questions about using titanium fasteners in your application, get in touch with the experts at Chemical Concepts.

-

Deform-nut M6 Titanium 9mm D x 16mm LOur Price Starting at $6.23

Deform-nut M6 Titanium 9mm D x 16mm LOur Price Starting at $6.23