Description

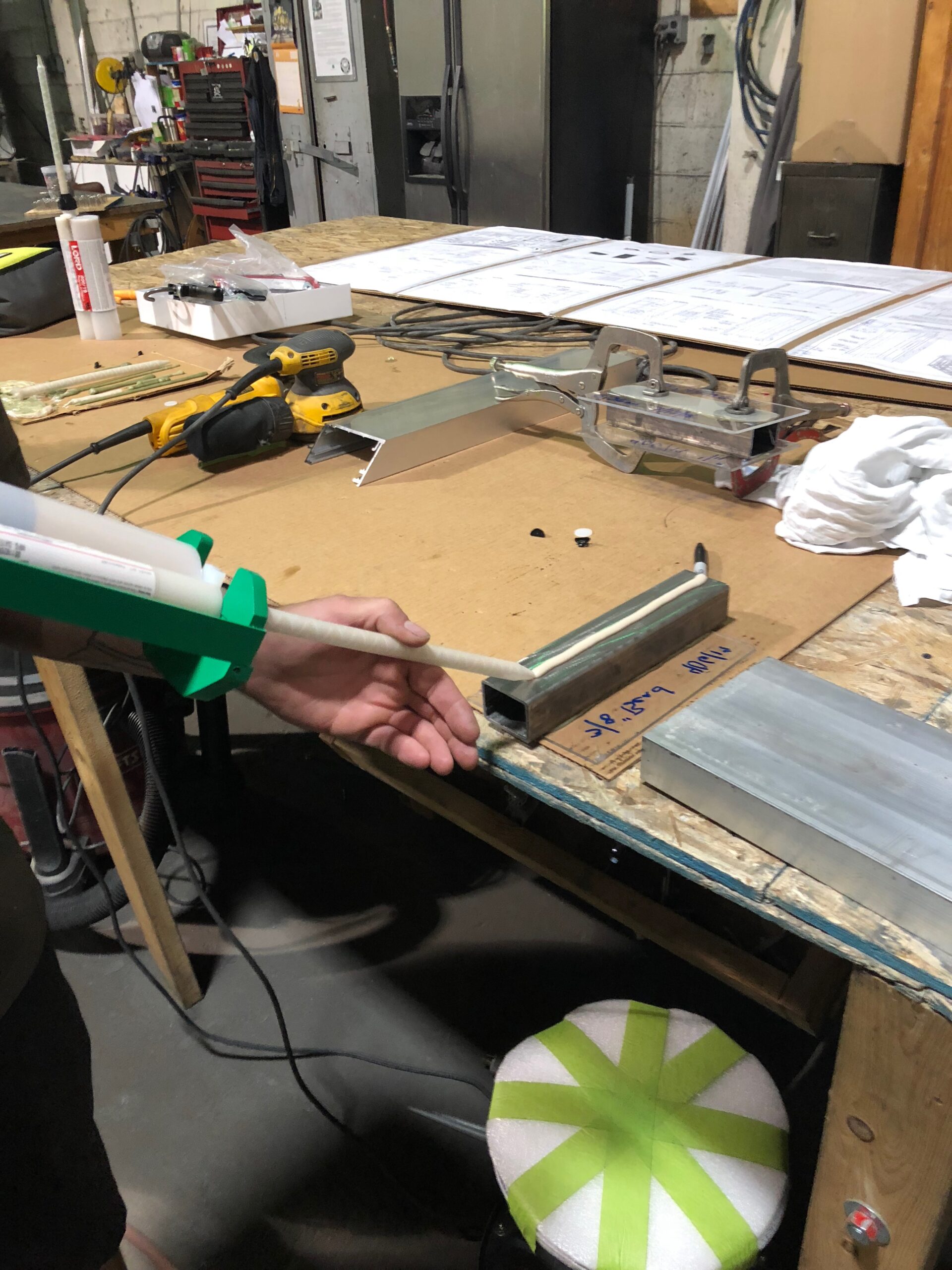

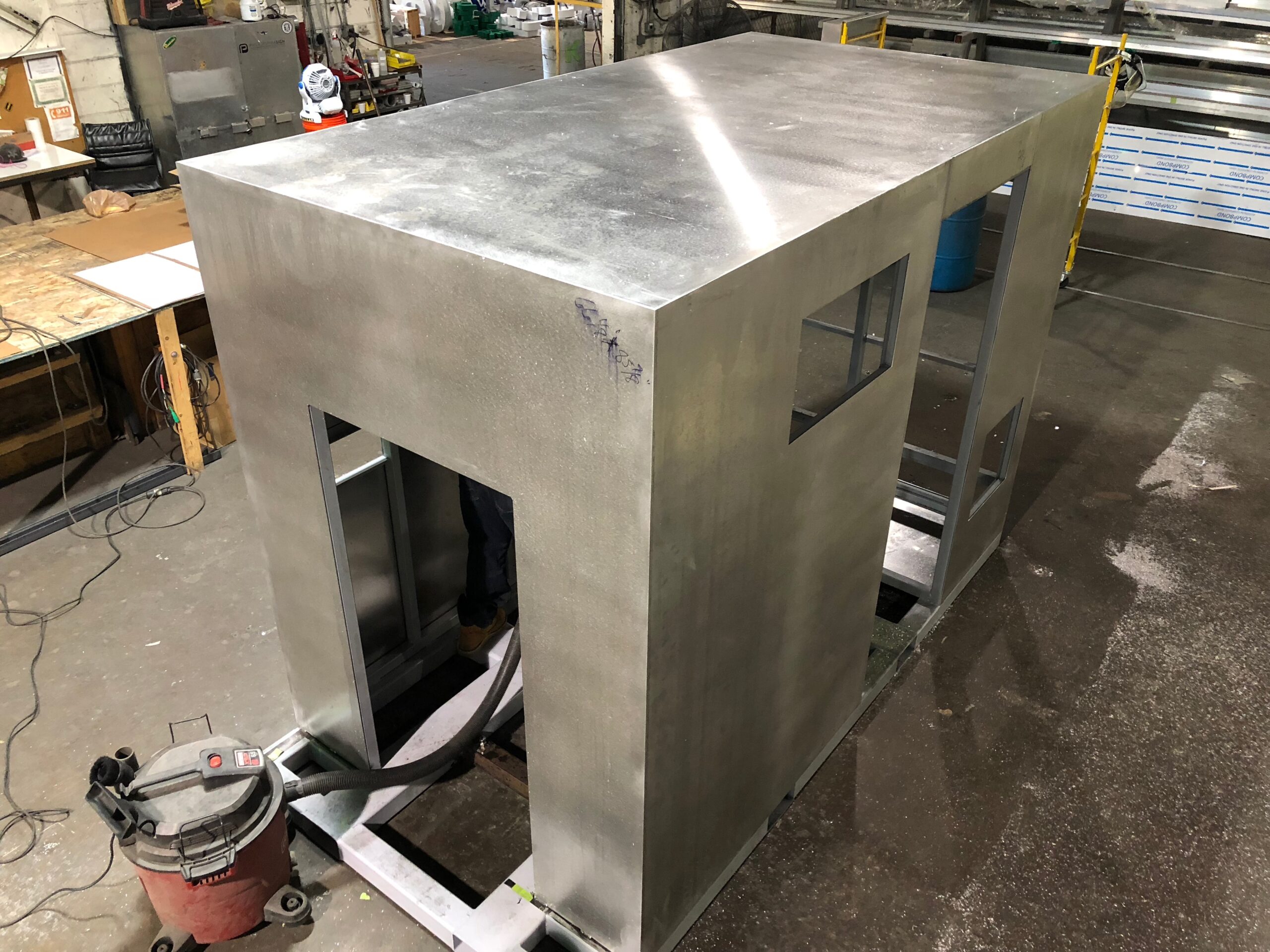

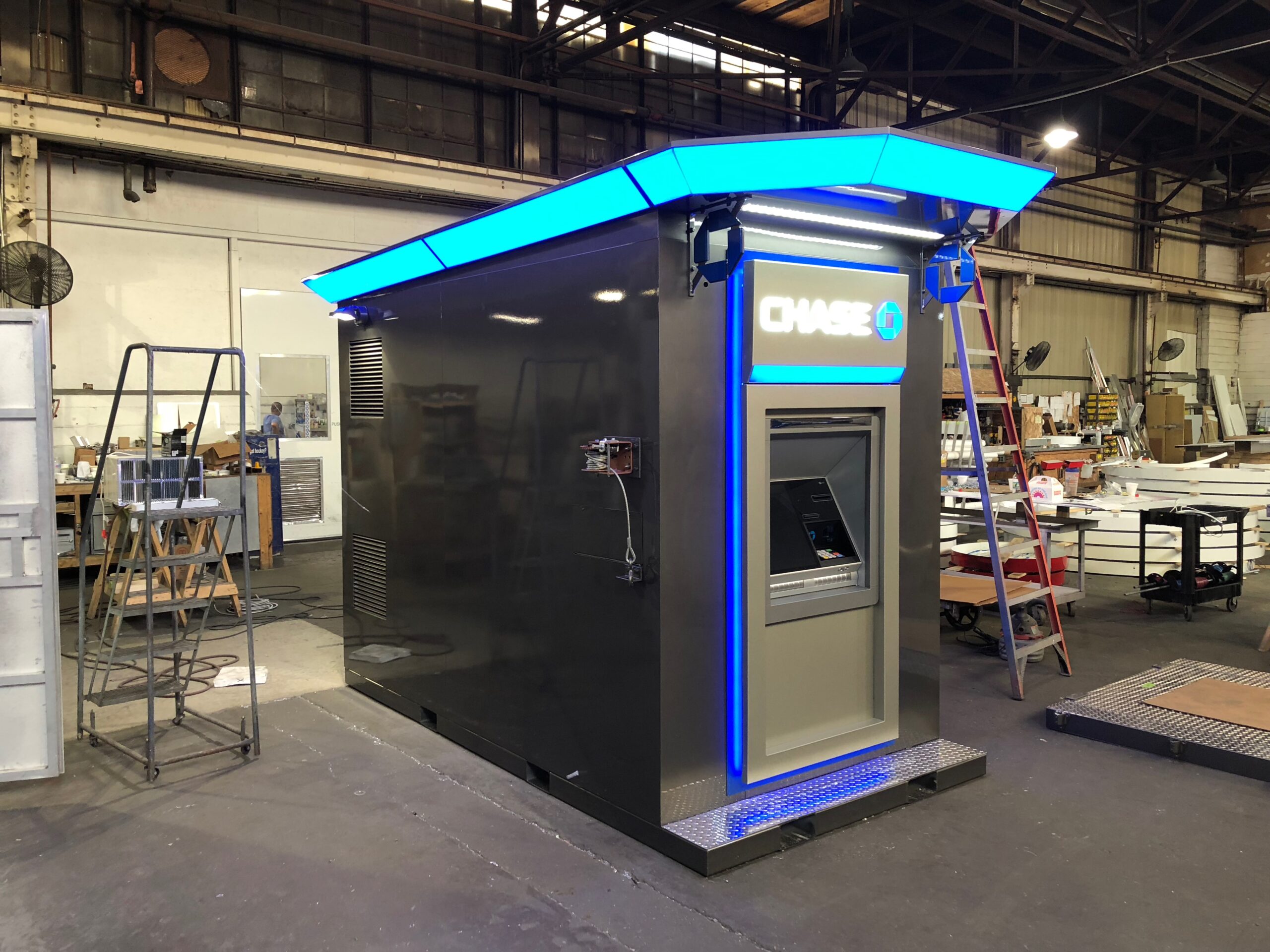

LORD® 410/19GB can be used to replace welding, brazing, riveting and other mechanical fastening methods. These adhesives perform particularly well in low-temperature environments and applications that are subject to high impact or high peel loads. LORD 403, 406 and 410 acrylic adhesives provide a range of working times to accommodate a wide variety of process requirements.

Features and Benefits

- Versatile–bonds a wide range of unprepared metals with minimal substrate preparation, as well as engineered thermoplastics including XENOY®, polycarbonate, ABS and acrylics

- Temperature Resistant– performs at temperatures from -40°F to +300°F (-40°C to +149°C).

- Envirnomentally Resistant– resists dilute acids, alkalis, solvents, greases, oils, moisture, salt spray and weathering; provides excellent resistance to indirect UV

- Non-Sag–remains in position when applied on vertical or overhead surfaces, allowing for greater process flexibility.

- UL Rated–when mixed with LORD Accelerator 19, adhesive system is UL 746C certified.

Typical Properties

| Appearance | Off-White to Tan Paste |

| Viscosity, cP @ 77°F (25°C) | 100,000 – 350,000 |

| Density, lb/gal (kg/m^3) | 9.15-9.65 (1096-1156) |

| Flash Point, °F (°C) | 59 (15) |

Typical Properties of Adhesive Mixed w/ Accelerator

| Mix Ratio by Weight | 3.02:1 |

| Mix Ratio by Volume | 4:1 |

| Solids Content, % | 100 |

| Working Time, min @ 75°F (24°C) | 20-45 |

| Time to Handling Strength, min @ 75°F (24°C) | 60-120 |

| Mixed Appearance | Tan Paste |

| Cured Appearance | Tan to Green |

Typical Cured Properties

| Tensile Strength at Break, psi (MPa) ASTM D638, modified |

4650 (32.1) |

| Elongation, % ASTM D638, modified |

30 |

| Young’s Modulus, psi (MPa) ASTM D638, modified |

130,000 (896.3) |

| Glass Transition Temperature, °F (°C) ASTM E1640-99, by DMA |

162 (72) |

Reviews

There are no reviews yet.