Description

Due to supply chain challenges the cartridge on this product is being changed. A new 415ml cartridge (3032004) replaces this original 375ml cartridge (3020503). This cartridge requires different guns and mixing tips compared to the old packaging. Please contact us with any questions regarding this change.

LORD® 406/19GB can be used to replace welding, brazing, riveting and other mechanical fastening methods. These adhesives perform particularly well in low-temperature environments and applications that are subject to high impact or high peel loads. LORD 403, 406 and 410 acrylic adhesives provide a range of working times to accommodate a wide variety of process requirements.

Features and Benefits

- Versatile – bonds a wide range of unprepared metals with minimal substrate preparation, as well as engineered thermoplastics including XENOY®, polycarbonate, ABS and acrylics.

- Temperature Resistant – performs at temperatures from -40°F to +300°F (-40°C to +149°C).

- Envirnomentally Resistant – resists dilute acids, alkalis, solvents, greases, oils, moisture, salt spray and weathering; provides excellent resistance to indirect UV.

- Non-Sag – remains in position when applied on vertical or overhead surfaces, allowing for greater process flexibility.

- UL Rated – when mixed with LORD Accelerator 19, adhesive system is UL 746C certified.

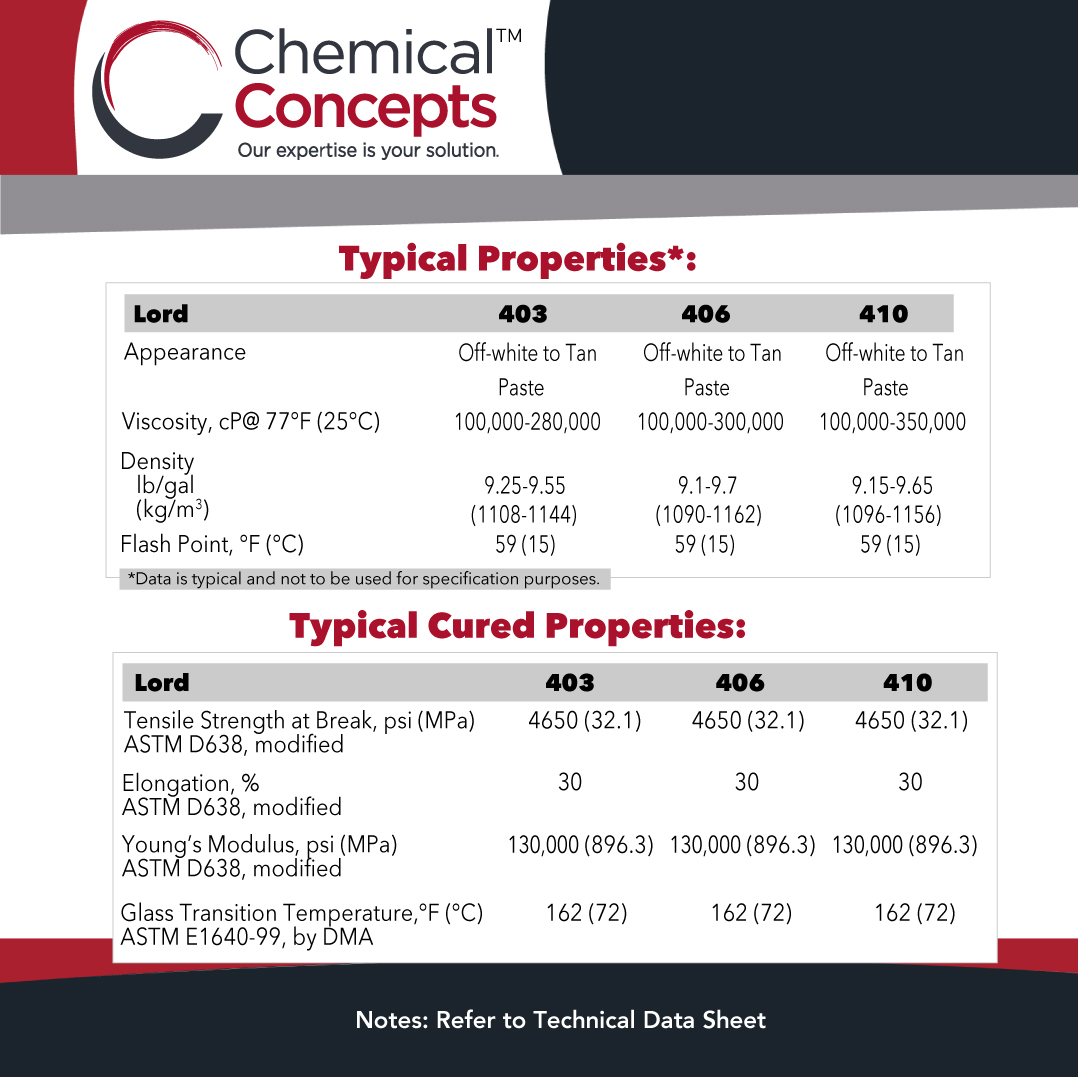

Typical Properties

| Appearance | Off-White to Tan Paste |

| Viscosity, cP @ 77°F (25°C) | 100,000 – 300,000 |

| Density, lb/gal (kg/m^3) | 9.1-9.7 (1090-1162) |

| Flash Point, °F (°C) | 59 (15) |

Typical Properties of Adhesive Mixed w/ Accelerator

| Mix Ratio by Weight | 3.02:1 |

| Mix Ratio by Volume | 4:1 |

| Solids Content, % | 100 |

| Working Time, min @ 75°F (24°C) | 6-10 |

| Time to Handling Strength, min @ 75°F (24°C) | 12-17 |

| Mixed Appearance | Tan Paste |

| Cured Appearance | Tan to Green |

Typical Cured Properties

| Tensile Strength at Break, psi (MPa) ASTM D638, modified |

4650 (32.1) |

| Elongation, % ASTM D638, modified |

30 |

| Young’s Modulus, psi (MPa) ASTM D638, modified |

130,000 (896.3) |

| Glass Transition Temperature, °F (°C) ASTM E1640-99, by DMA |

162 (72) |

Reviews

There are no reviews yet.