Description

PRODUCT DESCRIPTION

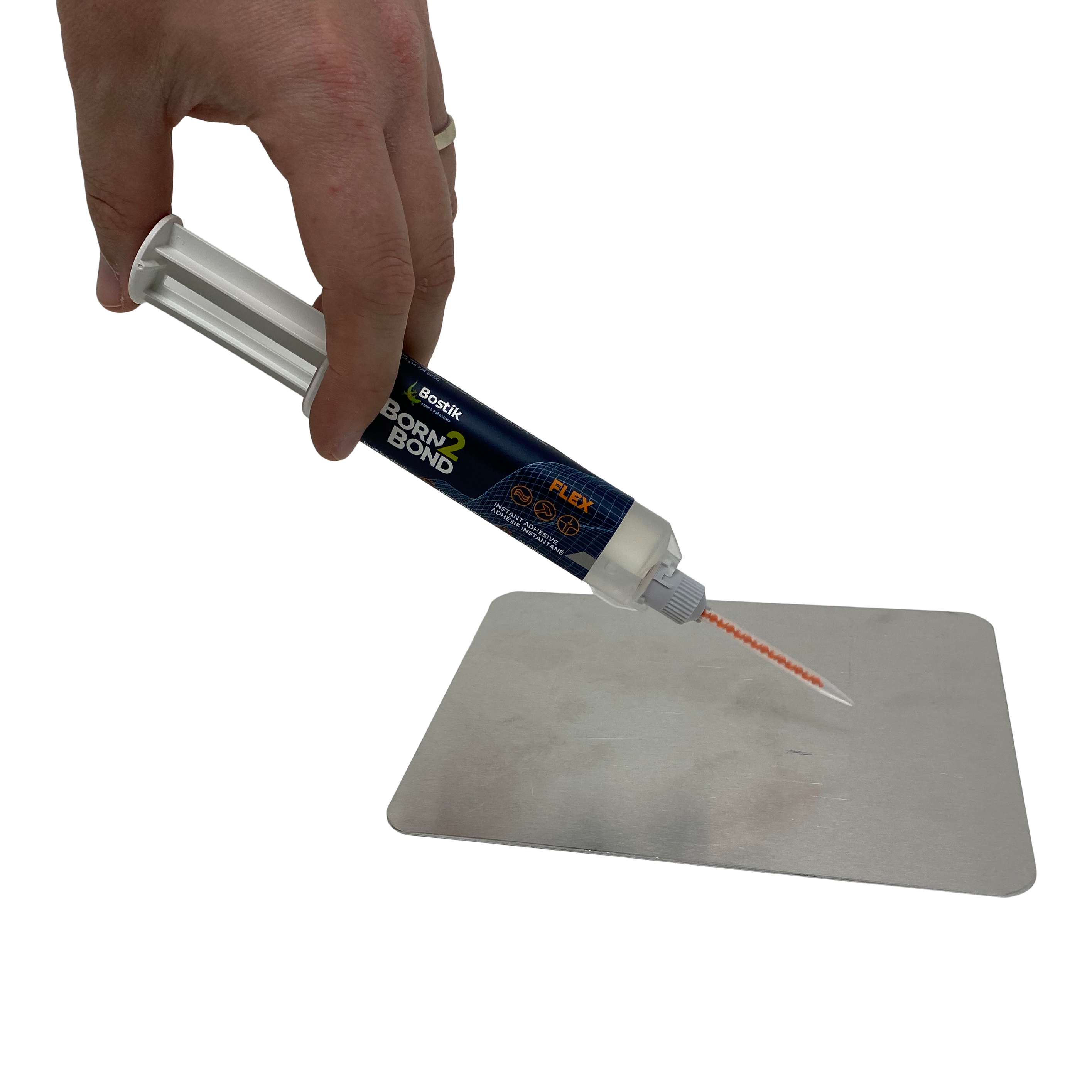

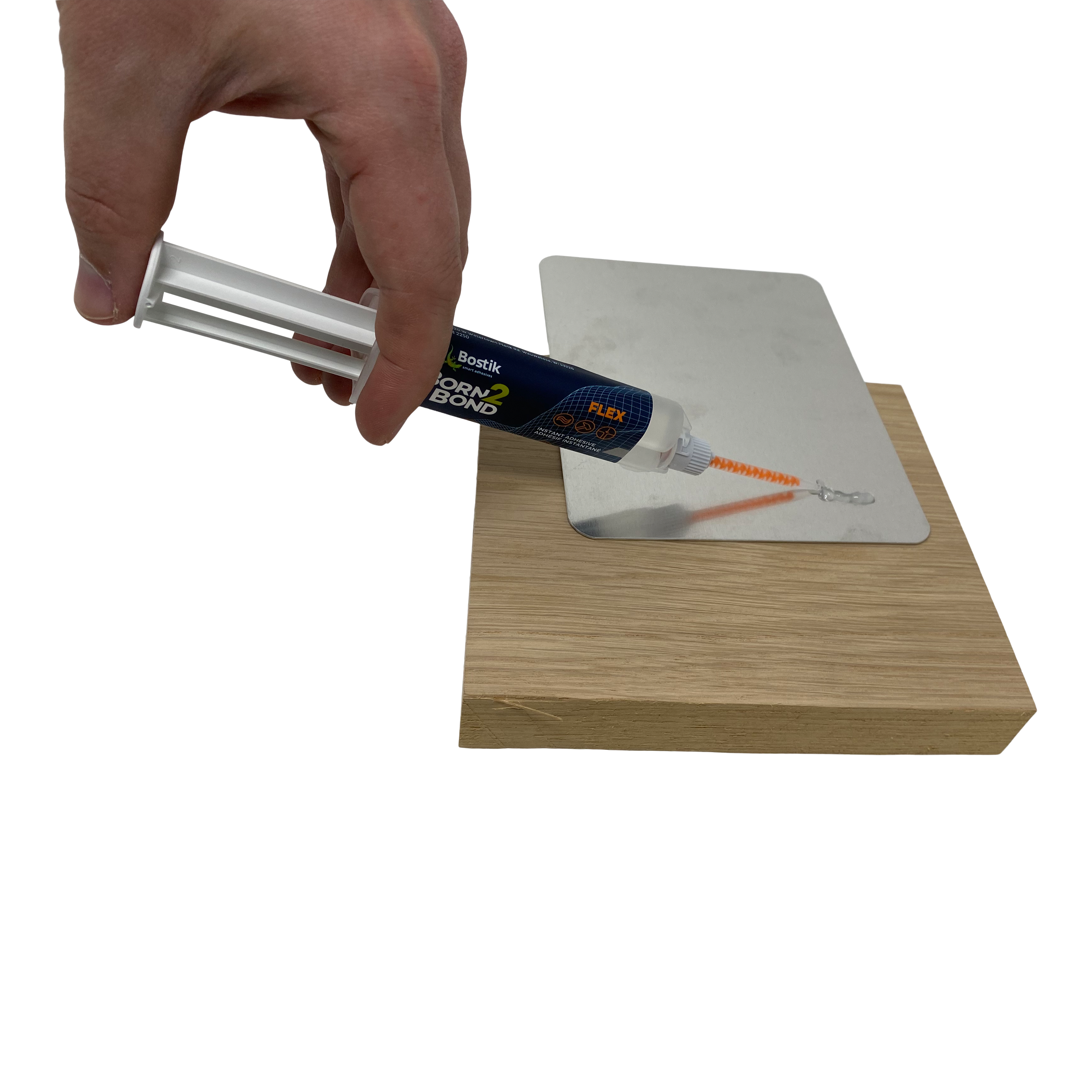

Born2BondTM Flex is a flexible, elastic and low-odor, instant

adhesive with exceptional adhesion to a very broad range of

materials and surfaces. It has a curing time of only six minutes

and becomes a polymer with more than 200% of elongation

within 10 minutes. Its working times (in-mixer) can be up to

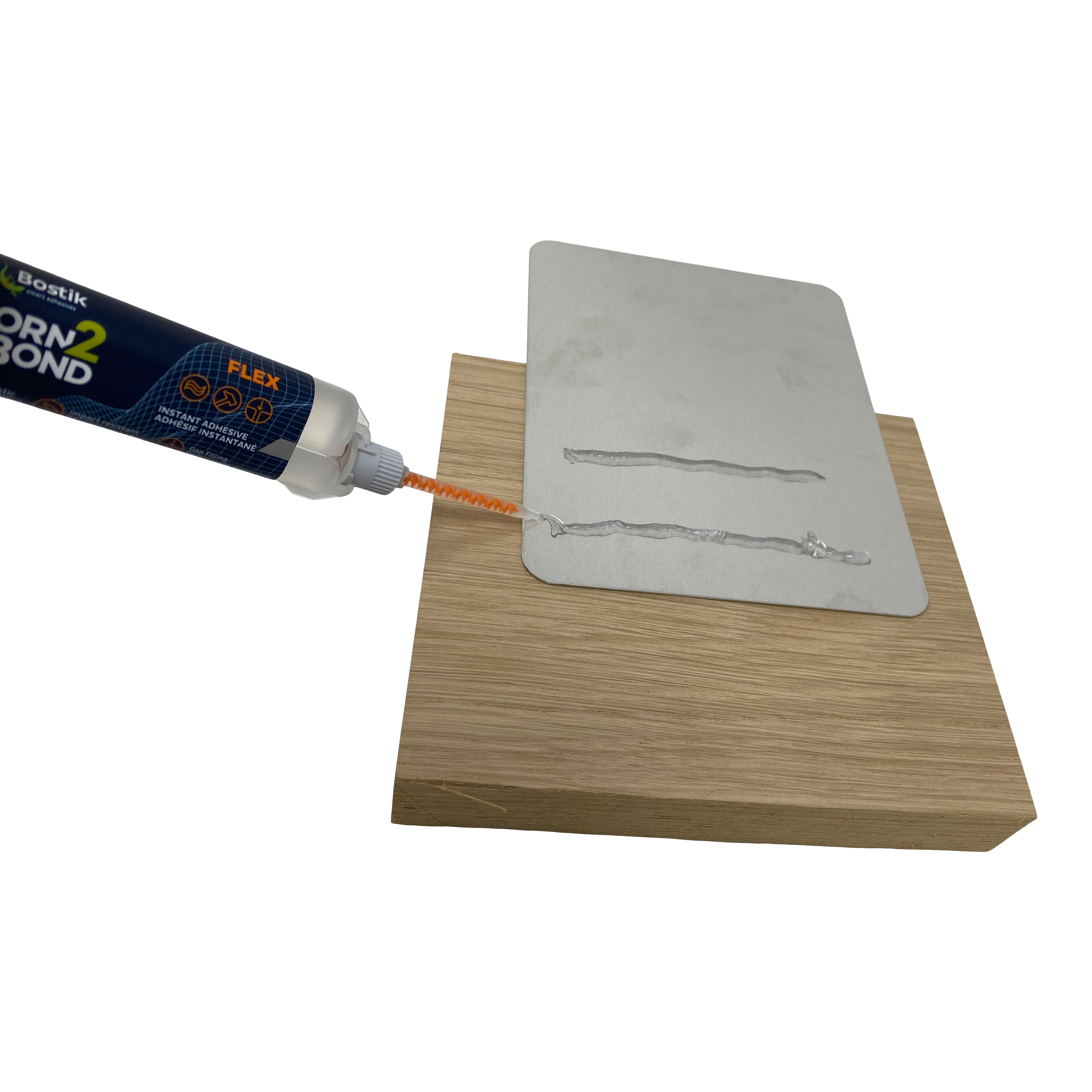

six minutes. It can be used for high-volumetric gap filling, and

achieves instant adhesion to most plastics, wood and metals and

to porous and irregular surfaces.

KEY FEATURES

→ Fixture time in 60 seconds*

→ Hardens in 5-10 minutes*

→ Elongation > 200 %

→ Absorbs impacts and vibrations

→ High peel strength

→ Bonds a large range of materials** including glass

→ Translucent, low blooming

→ Gel consistency for precise application

→ Non sagging for vertical applications

APPLICATIONS

The common applications of this product are bonding leather,

making elastic and waterproof joints, flexible bonding, bonding

floor coverings and particle boards, damping vibrations, reinforcing

parts, bonding glass and rubber.

PRODUCT CHARACTERISTICS

Base Technology – Part A/B Methoxyethyl cyanoacrylate (A) Plasticizer (B)

Components 1k – 2k 2k

Mix Ratio 4:1

Appearance/Color Transparent

Gap Filling Capacity 1 cm (0.39in)

Temperature Use Range -40°C to 60°C (-40°F to 140°F)

Open Time 6 – 10 mins

Mixer Life 6 – 10 mins

VOC Content – Part A 61 g/L

(ISO 11890-2)

VOC Content – Part B 19 g/L

(ISO 11890-2)

UNCURED PHYSICAL PROPERTIES

Viscosity at 25°C (77°F)* 120000 – 170000 cP @ 1.5 rpm

– Part A 6000 – 9000 cP @ 50 rpm

Viscosity at 25°C (77°F)* 70000 – 130000 cP @ 1.5 rpm

– Part B 3000 – 7000 cP @ 50 rpm

Specific Gravity 1.12 g/mL (A)

(ASTM D1875: 23°C / 73.4°F) 1.10 g/mL (B)

Refractive Index, ABBE 1.48 – 1.50

*based on Brookfield viscometer

CURED PHYSICAL PROPERTIES

Shore Hardness A (ISO 868-2003) 76

Tensile Strength (ISO 527) 2 MPa

Elastic Modulus (ISO 527) 2 MPa

Elongation at Break (ISO 527) 259%

Glass Transition Temperature 35°C (95°F)

(ISO 6721)

Linear Shrinkage (ISO 10563) 9.2%

Water Absorption (after 24 hrs) 11.3%

(ASTM D-542)

Impact Resistance (after 24 hrs) 21.0 kJ/m2

(ISO 9653)

Electrical Properties of Resistivity IEC 60093

Surface resistivity DC 500 V (Ohm) 3.7·1014

Volume resistivity DC 1kV (Ohm.m) 3.2·1010

Corrected Dissipation Factor, Dielectric Constant IEC 60250

D @ 1 kHz 0.06

k’ @ 1 kHz 3.55

BONDING PERFORMANCE

Lap shear strength (ISO 4587) @ 23°C (73.4°F) (MPa)

after 24 hours curing @ RT

Grit-Blasted Mild Steel (GBMS) 10 +/- 2

Aluminum (A5754) 5 +/- 1

ABS 6 +/- 1 SF

PVC 2 +/- 1

Phenolic 4 +/- 1

Polycarbonate 5 +/- 1 SF

@ 100mm/min after 24h Curing at RT

Nitrile 0.02 +/- 0.05

Neoprene 0.02 +/- 0.05

@ 2 mm/min after 1 week Curing at RT

Grit-Blasted Mild Steel (GBMS) 11 +/- 1

T-Peel Strength (ISO 11339) @ 23°C (73.4°F) (N/mm)

@ 100mm/min after 24 h curing @ RT

Mild Steel 1 +/- 0.3

Reviews

There are no reviews yet.