Hate Working with Quartzite?

Quartzite is in high demand, but these temperamental stones can create expensive and frustrating problems for fabricators.

See below for tips and tricks that can help you tackle these jobs without the headaches

Problem: Silicone Stains

Cause: Most 100% RTV silicone on the market is acetoxy silicone, which can cause bleeding on quartzite.

Solution:

Silco RTV-7500 Neutral Cure Silicone

- RTV-7500 is a neutral cure silicone which is non-bleeding

- Added bonus: Neutral cure silicones are low odor

- Stock Colors: Clear, White, Translucent White, Black

Problem: Bleeding

Cause: Standard seaming adhesives can cause bleeding

Solution: Use a specialized, non-bleeding seaming adhesive for delicate quartzites and marbles

- Integra Ultra is a cartridge color-matched “hybrid polyaspartic” seaming adhesive which is non-bleeding

- Integra Ultra’s formulation is made as a highly flexible, non-yellowing, non-reactive seaming adhesive

- Great for indoor and outdoor use

- Non-bleeding

- Interior and exterior applications

- Zero yellowing

- Laminating, seaming, & more

- Fast Cure

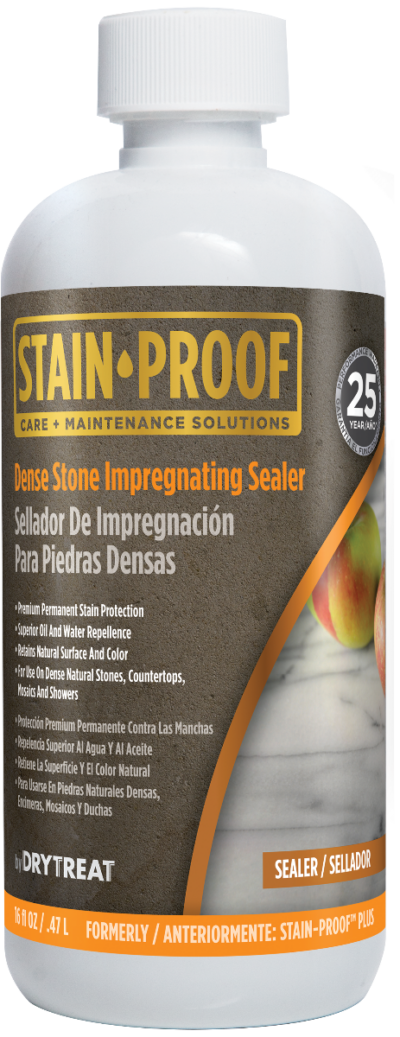

Problem: Sealing

Cause: Quartzites are notorious for retaining moisture and being difficult to seal

Solution:

StainProof Dense Stone Sealer (25 yr)

Allow stone to completely dry before applying sealer

- Deep-impregnating sealer gives better protection against entrapped moisture

- Excellent for difficult-to-seal stones

- Great results on marbles, quartzite, delicate stones

Problem: Difficult to Cut

Cause: Quartzite is difficult to cut often requiring slow speeds and multiple passes that create bottlenecks in the shop. Not to mention problems with chipping…

Solution:

- S-Complex is a cutting aid to assist with faster and cleaner cuts

- Increase cutting speeds by 3-9x

- 30% better diamond life

- Cut dense quartzite in a single pass

Do any of these problems sound familiar? Say goodbye to callbacks and check out these simple solutions to improve your results with quartzite today!