Choosing the Right Adhesive

Your Express Guide for Finding the Right Adhesive for your Project

Thanks to our friends at Permabond, a leader in the arena of engineering adhesives of all sorts, we’ve compiled a guide to aid you in choosing the most effective adhesive for your particular project. For more detailed information, feel free to download Permabond’s brochure PDF. Please also reach out to our sales team with any questions about Permabond’s products. Chemical Concepts is a preferred distributor for Permabond.

Thanks to our friends at Permabond, a leader in the arena of engineering adhesives of all sorts, we’ve compiled a guide to aid you in choosing the most effective adhesive for your particular project. For more detailed information, feel free to download Permabond’s brochure PDF. Please also reach out to our sales team with any questions about Permabond’s products. Chemical Concepts is a preferred distributor for Permabond.

There is a lot that goes into selecting the right adhesive for your job, like the surfaces that you’re bonding and the atmosphere you’re bonding in. There are also many options in the world of adhesives, each having its own set of advantages, specialties, and limitations. Below is an analysis of seven commonly used adhesives and how they stack up and compare with each other.

Anaerobics

- Preferred Surface(s) – Metal Only

- Pros – Seals well and more than adequately guards against corrosion

- Cons – Can only be used on metal surfaces

Cyanaoacrylates

- Preferred Surface(s) – Plastic (best), metal, rubber

- Pros – Cures rapidly and bonds a wide variety of substrates

- Cons – Poor resistance to polar solvents

Two-Part Acrylics

- Preferred Surface(s) – Metal (best), plastic

- Pros – High strength and good impact resistance

- Cons – Mixing is required

No Mix Acrylics

- Preferred Surface(s) – Metal, glass

- Pros – Highly flexible with good impact resistance

- Cons – Two step application is required

One Part Epoxies

- Preferred Surface(s) Metal & glass (best), wood

- Pros – Strong, no mix required

- Cons – Heat is required

Two Part Epoxies

- Preferred Surface(s) – Metal & glass (best), wood

- Pros – Strong, cures at room temperature

- Cons – Mixing required

UV Light Cured

- Preferred Surface(s) – Glass (best), plastic

- Pros – Cures rapidly, good adhesion to plastics, glass & metals

- Cons – Curing equipment is required

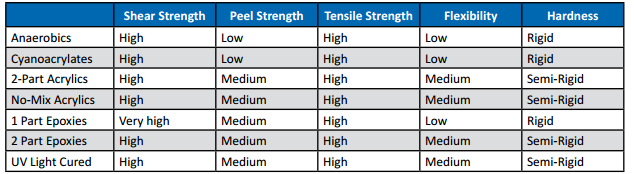

Rating Strength & Flexibility

Shear Strength – 1 Part Epoxies are king in the category of shear strength, although each adhesive category scores highly. Shear strength is essentially the ability of the adhesive or more generally, the material, to withstand forces that can cause the internal make-up of the material to break down.

Peel Strength – This class of adhesives actually scores fairly low with peel strength, every type garnering an “average” score other than Anaeorobics and Cyanoacrylates, which are considered to be poor. To get technical, peel strength is the measurement of the average load per unit width of bond line needed to part the two bonded materials.

Tensile Strength– Every adhesive, from Anaerobics to UV cured, score favorably with tensile strength, or the strength required to pull something before the stress of the pulling action causes bond failure.

Hardness – Anaerobics, Cyanoacrylates, and One-Part Epoxies are classified as rigid, and both forms of Acrylics, Two-part Epoxies, and UV Cured adhesives are classified as semi-rigid.

Flexibility – Two-Part and No Mix Acrylics, Two-Part Epoxies, and UV Cured adhesives are the leaders in this category, although they are considered to be about average.

What types of adhesives are the best with Temperature Resistance?

The best – One-Part Epoxies & Anaerobic adhesives score the best with heat resistance, with standard formulas for each being able to withstand temperatures of 150 degrees Celsius. Special grades of both can easily exceed 200 degrees Celsius.

Note: Certain “special grades” of Cyanoacrylates can actually approach 250 degrees of temperature resistance, but most standard grades can only withstand about 75 degrees.

The worst – Two-Part Epoxies have the lowest standard resistance of 75 degrees with special grades only being able to withstand 125 degrees of heat. UV Cured adhesives and Acrylics are also subject in this category, having standard grades that can resist 125 degrees of heat and no special grades available.

We hope this guide helps you choose the most appropriate adhesive for your next project, factoring temperature resistance, strength, flexibility, and surface characteristics.

Learn more by calling (800-220-1966) or emailing our sales team!